Purgex to Offer Free Expert-Led Processing Seminars at NPE2018

Neutrex Inc., manufacturer of Purgex Purging Compounds for the plastics industry, will showcase the latest developments in its broad range of purging compounds for injection molding,

Neutrex Inc., manufacturer of Purgex Purging Compounds for the plastics industry, will showcase the latest developments in its broad range of purging compounds for injection molding, extrusion, blow molding, and film and sheet applications at NPE2018 May 7-11 at the Orlando County Convention Center in Orlando, Fla. Attendees are invited to Purgex Purging Compounds’ Booth #S20035 for free educational yet entertaining seminars by plastics processing experts John Bozzelli (injection molding) and Allan Griff (extrusion).

Bozzelli provides expertise in resin characterization and analysis and his specialty is practical, hands-on injection molding training in plastics, rubber, LIM/LSR, metals, wax, ceramics, medical validations, and infrared thermography. He is known for his contagious passion for processing and presents practical techniques that help processors improve productivity and boost profits. Bozzelli’s presentations, “How to Minimize Black Specks” (Monday), “How to Set Barrel Temperatures” (Tuesday), and “How Plastics Melt” (Wednesday) will be held at 10 a.m.

Consulting technical engineer Allan Griff will present “The Ten (11) Key Principles of Extrusion” on Monday, Wednesday, and Thursday at 2 p.m. and “Plastics Chemistry for Non-Chemists” on Tuesday at 2 p.m. and Thursday at 10 a.m. Author of “The Plastics Extrusion Operating Manual,” Griff is known through his seminars, in-house training, and webinars as an intuitive problem solver. Attendees will have the opportunity for one-on-one sessions with Griff during the show.

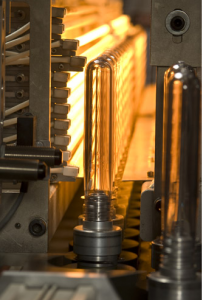

At NPE2018, Neutrex will discuss the latest in Purgex Purging Compounds, which speed up color changes, eliminate contamination, reduce rejects, and decrease downtime. Purging compounds from Purgex are engineered to efficiently clean the barrel, screw, check ring, nozzle and hot runner systems in injection molding equipment and to effectively clean extrusion, blow molding, and film and sheet equipment.

Neutrex delivers chemical engineering experience, technology, and the results of its on-site R&D lab testing and in-plant trials to every specialized product in its line of commercial purging compounds. Purgex grades are comprised of active ingredients with a resin carrier and are engineered to clean thoroughly and quickly to maximize color/resin change turnaround and reduce scrap. Most grades are designed for versatility and are effective on a broad range of resins and multiple production methods for applications ranging from large automotive instrument panels to small medical components. Purgex Purging Compounds are available through a broad global distribution network.

Neutrex Inc., based in Houston, is the manufacturer of Purgex Purging Compounds, a line of top-quality, high-value, competitively priced commercial purging compounds. Purgex has been used worldwide in injection molding, extrusion, and blow molding applications.

These products have mechanical activity for effective cleaning of thermoplastic resins from injection molding machines, extruders, hot runner systems, and dies. Purgex grades are comprised of active ingredients with a resin carrier and are engineered to clean thoroughly and quickly to maximize color/resin change turnaround and reduce scrap. Most grades are designed for versatility and are effective on a broad range of resins and multiple production methods.